Will Sound Screws Revolutionize Soundproofing?

The Internet is abuzz with the announcement of Sound Screws. Developed by researchers from Malmö University in Sweden and officially titled the “Revolutionary Sound Absorbing Screw,” Sound Screws are spring-loaded drywall screws meant to turn your walls into sound-absorbing panels. So, how do they work, and will Sound Screws revolutionize the way we soundproof home theater rooms?

How Sound Screws Work

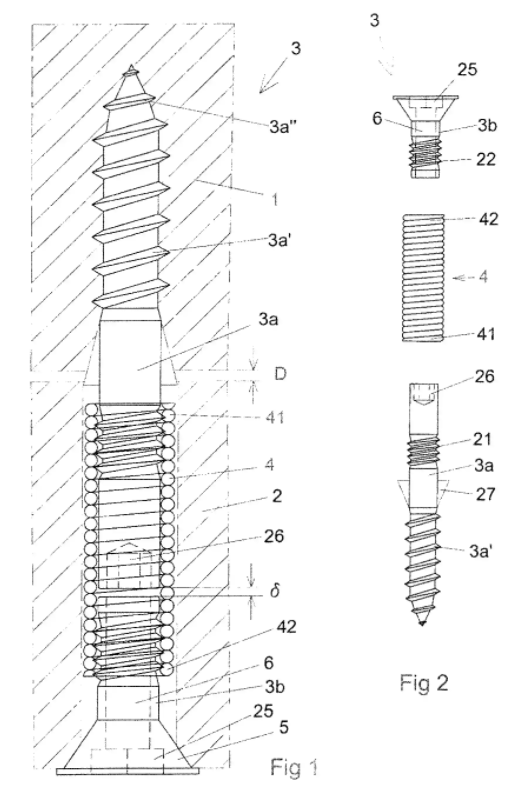

The premise behind the Sound Screw is simple. You replace your normal screws with the Sound Screw. The Sound Screws have three main parts: The head, the body, and the spring.

You install the screw with a normal driver. Pressure on the head seats it into the body. After installation, and pressure is released, the spring snaps back into place, decoupling the drywall from the studs. In theory, these screws should be just as easy to install as any other screw. The decoupling of the drywall from the structure has resulted in up to a 9dB reduction of sound transmission as reported by the creator.

Advantages of Sound Screws

There are two main things to think about when constructing anything – material cost and labor cost. Traditional methods of reducing sound transmission between rooms require the use of extra or more expensive materials (QuietRock, double layers of drywall, Green Glue, etc.) or extra labor to install decoupling solutions (hat channels, sound clips, etc.). In both cases, these solutions actually eat up more real estate in your room by making your walls thicker. Sound Screws promise a solution that won’t reduce your square footage.

Aside from saving space, the labor costs and material costs may be much less. Drywall is already installed with screws, the Sound Screws are just a different option. You are also not required to purchase additional sheets of drywall or extra materials. This saves not only on material costs, but installation time and labor costs.

Disadvantages of Sound Screws

If Sound Screws are going to revolutionize soundproofing, they can’t just save on costs. They have to be easy to use. One question that hasn’t been answered is how the Sound Screws can be used. Drywall screws can be loaded automatically into many drywall guns. If the Sound Screws have to be hand-loaded, many of the labor cost advantages may evaporate.

We also have to look at the price per screw. Drywall screws just aren’t that expensive. You can get many thousands for less than a couple hundred dollars. Sound Screws just haven’t the economy of scale that you’d need to compete. That means a more expensive screw (per unit) with more labor (and aggravation) costs.

Lastly, drywall screws are rated for the thickness of drywall. Different screws for different thicknesses. There is no word on how the Sound Screws will handle 1/2″ drywall versus 5/8″. We are also curious about how the decoupling will affect the mud and tape used to hide screws. Will leaning on the wall cause the screw heads to push through? We won’t know until we see them in action.

Our Take

We are tentatively excited about the Sound Screw announcement. There are still a lot of questions to be answered (you can’t even buy them outside of Sweden yet), but this could be a nice alternative to some of the more costly and labor-intensive soundproofing solutions. Do we think the Sound Screws will revolutionize soundproofing? Not really. But if they started being used more often in home construction, that wouldn’t be a bad thing. We’ll keep a close eye on the Sound Screws going forward and let you know if there are any interesting developments.

Dts sound